Ongoing Research

-

Micromatter Graphene Based Foils

In response to customer enquiries, Micromatter Technologies’ recent R&D efforts focused on the manufacture of novel carbon foils containing graphene structures. Several commonly used processes, such as filtration of graphene nanoparticles, pressing of aqueous graphene slurry, and high temperature pyrolytic decomposition of polyimide films were investigated. All techniques yielded carbon foils of high thickness (25 to 35 µm) and low density, however, their mechanical properties were inferior to Micromatter’s standard diamond-like carbon (DLC) foils. Attempts to produce thin films of 1 to 5 µm thickness were entirely unsuccessful.

Based on our previous experience in the fabrication of DLC films we investigated the pulsed laser ablation of ultra-pure highly oriented pyrolytic graphite (Minteq Pyroid®).

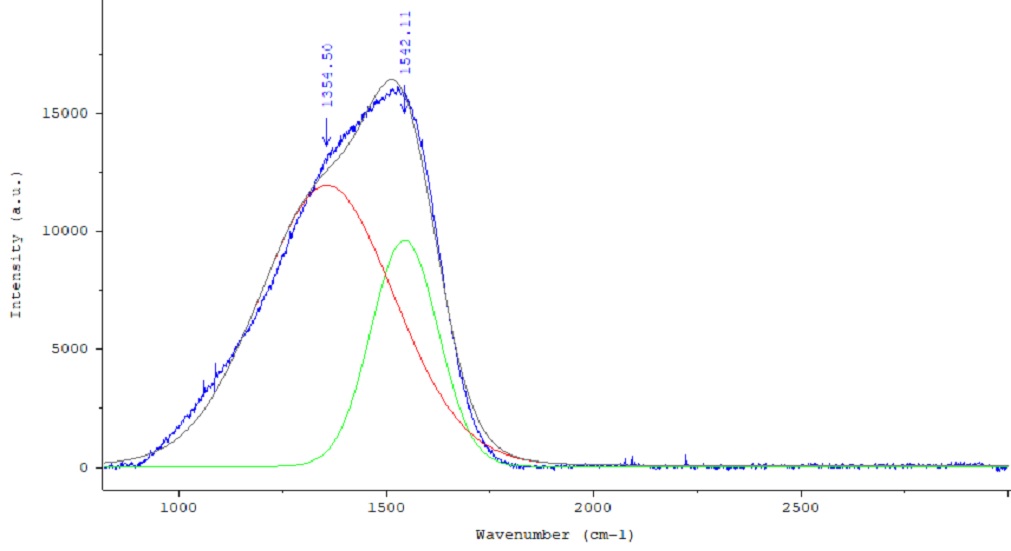

This process yielded carbon foils of amorphous structure, as indicated by a broad asymmetrical band at 1540 cm-1 in the Raman spectrum, which is typical for diamond-like carbon. Micromatter graphene foils have an sp3 content of approximately 28%, as calculated from the height of the resolved D and G bands at ~1350 cm-1 and ~1580 cm-1, respectively; the rest (~72%) is sp2 carbon. Micromatter now offers highest quality graphene based carbon foils that are extremely flexible, mechanically robust and free of pinholes. Due to their outstanding thermal properties graphene foils are particularly suited for beam stripping at high power densities and as target backings for heavy ion applications.

Figure 1 Below : Baseline corrected Raman spectrum of Micromatter graphene foil. Spectra were recorded with a LabRam spectrometer equipped with a BX40 Olympus microscope in backscattering geometry (180o). An Ar+ ion laser (514.5 nm wavelength) and an 1800 gr/mm grating were used in these measurements.